This is part one of the two part poster that was presented at the Health Physics Society annual meeting held in Salt Lake City, Utah, June 27th - July 1st, 2010. Part two will be coming soon. Select the link for the affiliated paper in Radiation Physics and Chemistry, Volume 80, Issue 1, January 2011, Pages 107-113.

Abstract

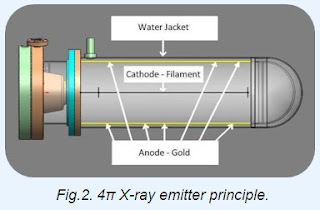

For high-energy photons (5-10 MeV), high powered X-ray irradiators have already been used for industrial applications, such as materials modification, food processing, and medical device sterilization. Now it seems possible to have smaller self-shielded irradiators with X radiation that can provide a very attractive alternative to self-shielded gamma ray irradiators. This has been made possible with the advent of the new technology, using 4π X-ray Emitters. The crucial characteristic of these emitters is a large distributed anode emitting photons in almost 4π geometry; this decreases the target cooling requirements, resulting in a higher power input and thus high dose rate. Of necessity, these irradiators have much smaller photon energies, maximum being 160 keV. However, the ultimate acceptance depends on the performance of these low-energy X-ray irradiators. The most important performance criteria for judging their success include dose rate, dose uniformity, throughput, reliability, safety and ease of operation. Another important requirement would be availability of dosimetry systems, reference as well as routine systems for dose measurements. Experimental data are presented here for two types of such self-shielded X-ray irradiators, both based on the 4π technology. These data include maximum dose rate achievable, dose uniformity ratio, the volumes that can be treated in one cycle and description of the dosimetry systems. The data indicate that these self-shielded X-ray irradiators are capable of replacing gamma irradiators for several applications, including sterile insect technique, small animal research, radiation resistant microorganism research, medical device terminal sterilization and viral inactivation.

Introduction

Self-shielded gamma ray irradiators (with cobalt-60 or caesium-137 as an isotopic source) have been extensively used for research and many small-scale applications, including sterile insect technique, small animal research, radiation resistant microorganism research, medical device terminal sterilization and viral inactivation. However it has now become increasingly difficult to purchase, transport or reload such irradiators because of the increased controls on radioisotopes due to the fear of terrorism. Fortunately, it now seems promising to have similar self-shielded irradiators with X radiation that can provide a very attractive alternative to self-shielded gamma ray irradiators. This has been made possible with the advent of the newly developed and patented technology (Kirk and Gorzen, 2008), using 4π X-ray emitters.

Since such irradiators do not depend on an isotopic source for the production of radiation, the danger of them being misused is eliminated, which seems to be the primary drive behind the move to replace gamma ray irradiators with X-ray irradiators (National Academy of Sciences, 2008 ). Before these devices can be used extensively and accepted by the research and scientific community, it is essential that its performance be demonstrated. Much experimental work has been done on two types of irradiators based on this technology. To add to some published reports (eg., Wagner et al., 2009), we present here a wealth of data that show suitability of these irradiators for the research purposes and some applications.

The data presented here are for two types of irradiators, namely RS 2400 Figure 1a and RS 2500 Figure 1b; both using 4π X-ray emitters.

RS 2400: The rotator system consists of five sample containers  rotating around the X-ray emitter about 1.5 cm (variable) from the emitter surface in the fashion of a Ferris wheel, thus keeping their orientation fixed. The internal diameter and the length of the containers are 175 mm (variable) and 150 mm, resp. The wall of the container is made of ca. 1.4 mm carbon fibre reinforced resin, lined inside with 0.5-mm steel that acts as a spectrum-hardening filter. The volume of each container is about 3.5 litres giving a batch volume of about 17.5 litres.

rotating around the X-ray emitter about 1.5 cm (variable) from the emitter surface in the fashion of a Ferris wheel, thus keeping their orientation fixed. The internal diameter and the length of the containers are 175 mm (variable) and 150 mm, resp. The wall of the container is made of ca. 1.4 mm carbon fibre reinforced resin, lined inside with 0.5-mm steel that acts as a spectrum-hardening filter. The volume of each container is about 3.5 litres giving a batch volume of about 17.5 litres.

RS 2500: It consists of one sample container surrounded by two X-ray emitters at a distance of about 1.5 cm (variable) from the surface. The container is placed on a table which can be rotated around its own axis. The internal diameter of the container is about 7 cm (variable) and the height can be varied according to the required dose uniformity in the sample.

X-ray irradiators

Each irradiator consists of two units: the irradiation chamber which contains the X-ray emitter(s), control system, power supply, and rotator with container(s) and the cooling unit which contains a water tank, pump and heat-exchanger for cooling the X-ray emitter(s). Figures 1a and 1b show the irradiation chambers, which are externally similar for RS 2400 and RS 2500 (Rad Source Technologies Inc., 2009).

d from all points along the anode. Typically the radiation field is more than twenty times that of a conventional point source, whilst the power density per unit area of target is much reduced.

d from all points along the anode. Typically the radiation field is more than twenty times that of a conventional point source, whilst the power density per unit area of target is much reduced.Figures 3a and 3b show the arrangement of the sample container(s) and the X-ray emitter(s) for both types of irradiators. These geometries allow the sample to receive radiation from all directions in the rotation mode to improve dose uniformity. The characteristics are summarised in Table I.

Dosimetry systems

Dosimetry systemsReference dosimetry was carried out with a Farmer’s type 0.18 cm3 ionization chamber (supplied by RadCal Corporation, Monrovia, CA). It was calibrated in the photon energy range 50-1300 keV by the supplier with traceability to NIST (National Institute of Standards and Technology, MD, USA). Dose rate was measured at a reference location using this ionization chamber. Routine dosimetry was carried out using three types of radiochromic film dosimetry systems: two with Gafchromic® dosimeters and one with FWT dosimeters. The optical density (OD) was measured using a FWT Radiachromic® reader (FWT-92) for all the film dosimetry systems. For the calibration of these dosimetry systems, several dosimeters were irradiated at the reference location at each of several dose points in the desired dose range. Figures 4a and 4b show calibration curves for the Gafchromic DM 1260 dosimetry system and FWT dosimetry system.

Several experiments were carried out to study the effect of photon energy on the response of the Gafchromic film dosimeters. To change the photon spectrum at the centre of the container, the emitter was operated at 100 and 150 keV. The dose rate or (dose) was measured with the ionization chamber as well as with the Gafchromic dosimetry system (calibrated for 150 keV spectrum) for both these voltages. When exposed to the same field, the dose measured by the two sets of dosimeters differed by less than 3%, comparable with the uncertainty in the Gafchromic dosimetry system as well as the ionization chamber. Thus, it can be concluded that the response of the Gafchromic film dosimeters is energy independent in this photon energy range.