This is part two of the two part poster that was presented at the Health Physics Society annual meeting held in Salt Lake City, Utah, June 27th - July 1st, 2010. Select the link for the affiliated paper in Radiation Physics and Chemistry, Volume 80, Issue 1, January 2011, Pages 107-113.

Abstract (from part one of the two part poster)

For high-energy photons (5-10 MeV), high powered X-ray irradiators have already been used for industrial applications, such as materials modification, food processing, and medical device sterilization. Now it seems possible to have smaller self-shielded irradiators with X radiation that can provide a very attractive alternative to self-shielded gamma ray irradiators. This has been made possible with the advent of the new technology, using 4π X-ray Emitters. The crucial characteristic of these emitters is a large distributed anode emitting photons in almost 4π geometry; this decreases the target cooling requirements, resulting in a higher power input and thus high dose rate. Of necessity, these irradiators have much smaller photon energies, maximum being 160 keV. However, the ultimate acceptance depends on the performance of these low-energy X-ray irradiators. The most important performance criteria for judging their success include dose rate, dose uniformity, throughput, reliability, safety and ease of operation. Another important requirement would be availability of dosimetry systems, reference as well as routine systems for dose measurements. Experimental data are presented here for two types of such self-shielded X-ray irradiators, both based on the 4π technology. These data include maximum dose rate achievable, dose uniformity ratio, the volumes that can be treated in one cycle and description of the dosimetry systems. The data indicate that these self-shielded X-ray irradiators are capable of replacing gamma irradiators for several applications, including sterile insect technique, small animal research, radiation resistant microorganism research, medical device terminal sterilization and viral inactivation.

4π X-ray Emitter: Performance

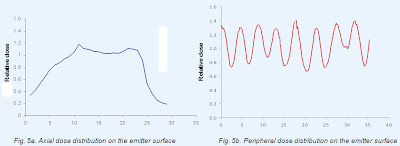

The photon field was measured on the surface of the X-ray emitter along the length as well as around the circumference using radiochromic film strips. Because of the structure of the emitter support and the central cathode, the photon field on the emitter surface is not very uniform (Figures 5a and 5b).

However, this does not seem to affect the dose distribution in the container. The nearly uniform field in the axial direction reflects the extent of the central cathode.

The dependence of the dose rate at the centre of a container was studied as a function of the emitter voltage. As expect

ed it shows a good quadratic relationship (Fig. 6, data for RS 2400). Also, the dose rate was linearly dependent on the emitter current. Because of the build-up of emitter current which takes finite time, there is what may be called a ‘transit dose’. Its value increases with current with a maximum of about 1.6 Gy at 150 kV and 55 mA.

ed it shows a good quadratic relationship (Fig. 6, data for RS 2400). Also, the dose rate was linearly dependent on the emitter current. Because of the build-up of emitter current which takes finite time, there is what may be called a ‘transit dose’. Its value increases with current with a maximum of about 1.6 Gy at 150 kV and 55 mA.The photon spectrum was determined mathematically using a Monte Carlo code by Prof. Uribe (Kent State University, personal communication) in the centre of a container filled with pupae for RS 2400 (Fig. 7).

As expected, the photon energy varies from about 30 to 150 keV, with a broad peak at about 60 keV.

Effect of rotation on dose variation

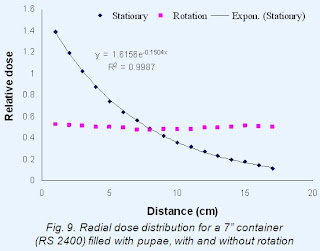

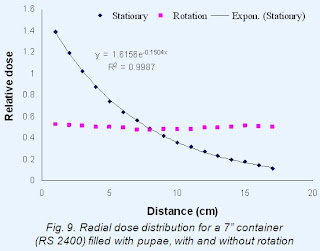

It is interesting to note the relationship between the radial dose distributions within a container for the rotational mode and for the stationary mode.

Dose distribution in the container

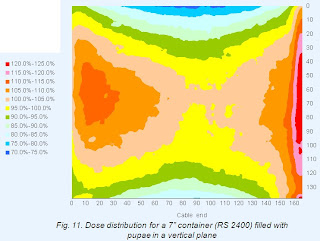

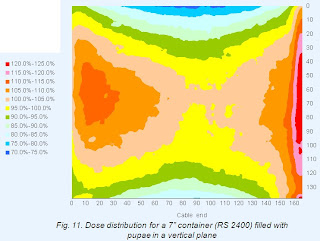

For RS 2400, this dose distribution was also measured by irradiating a large 14.5 x 17.2 cm Gafchromic sheet in the container filled with pupae. The irradiated dosimeter sheet was scanned in reflectance mode on an Epson 10000 XL flatbed scanner (model J181A) at 48 bits per pixel and 50 dpi. The calibration was used to calculate dose values which were then expressed as a proportion of the central dose (Fig. 11).

For RS 2400, this dose distribution was also measured by irradiating a large 14.5 x 17.2 cm Gafchromic sheet in the container filled with pupae. The irradiated dosimeter sheet was scanned in reflectance mode on an Epson 10000 XL flatbed scanner (model J181A) at 48 bits per pixel and 50 dpi. The calibration was used to calculate dose values which were then expressed as a proportion of the central dose (Fig. 11).

Radiation field in the container

Hardening the photon energy spectrum

Preliminary experiments indicated that the photon energy spectrum would need to be hardened to achieve more uniform dose within the large (7” diameter) container used in RS 2400. Sleeves of different materials and various thicknesses were inserted within the container, adjacent to the carbon fiber wall.

Hardening the photon energy spectrum

Preliminary experiments indicated that the photon energy spectrum would need to be hardened to achieve more uniform dose within the large (7” diameter) container used in RS 2400. Sleeves of different materials and various thicknesses were inserted within the container, adjacent to the carbon fiber wall.

Figure 8 shows the effect of 1-mm brass and 0.5-mm steel on the radial dose distribution in a 7” container in rotational mode. Since 1-mm brass depressed the dose rate significantly, we selected 0.5-mm steel for the hardening filter for all the containers. Spectrum hardening within the container is achieved since the filter absorbs low-energy photons more than the high-energy ones. All data presented here for RS 2400 are with 0.5-mm steel filter.

Effect of rotation on dose variation

It is interesting to note the relationship between the radial dose distributions within a container for the rotational mode and for the stationary mode.

Figure 9 shows data for a 7” container filled with pupae (for RS 2400); both runs had similar operating parameters. In the stationary mode, the dose variation fits an exponential quite well showing that the dose decreases by about 15% per cm, and the dose has decreased by about a factor of 10 across the diameter. While rotating the container around the X-ray emitter gives a max/min ratio of about 1.08!

Dose distribution in the container

The 2-dimensional dose distribution within a container was measured by placing several long strips of film dosimeters within the container along the axis as well as along the diameter. The irradiated films were measured and the calibration was used to calculate dose values which were then expressed as a proportion of the central dose; the results are shown in figures 10a and 10b, for RS 2400 and RS 2500, respectively.

For RS 2400, this dose distribution was also measured by irradiating a large 14.5 x 17.2 cm Gafchromic sheet in the container filled with pupae. The irradiated dosimeter sheet was scanned in reflectance mode on an Epson 10000 XL flatbed scanner (model J181A) at 48 bits per pixel and 50 dpi. The calibration was used to calculate dose values which were then expressed as a proportion of the central dose (Fig. 11).

For RS 2400, this dose distribution was also measured by irradiating a large 14.5 x 17.2 cm Gafchromic sheet in the container filled with pupae. The irradiated dosimeter sheet was scanned in reflectance mode on an Epson 10000 XL flatbed scanner (model J181A) at 48 bits per pixel and 50 dpi. The calibration was used to calculate dose values which were then expressed as a proportion of the central dose (Fig. 11).

Dose uniformity for the 7” container for RS 2400 is better than ±15% over the container volume of 3.5 liters. While for 3” container for RS 2500, it is ±10% over the container volume of about 0.5 liters.

Conclusions

These new, self-shielded X-ray irradiators will fulfil the requirements of processing capacity, dose rate, dose uniformity and ease of use required for research and many small-scale applications, including sterile insect technique, small animal research, radiation resistant microorganism research, medical device terminal sterilization and viral inactivation. They, therefore, provide a practical alternative to self-shielded gamma ray irradiators with associated safety.

References

Kirk, R.E., Gorzen, D.F. 2008. X-ray tube with cylindrical anode. USA Patent number 7,346,147 B2.

National Academy of Sciences, 2008. Radiation source use and replacement: Abbreviated version. The National Academies Press, Washington. Available from: http://www.nap.edu/catalog/11976.html Accessed: Feb 5, 2010.

Rad Source Technologies Inc., 2009. RS 2400 - X-ray high volume irradiator. Available from: http://www.radsource.com/products/products.php?id=rs2400 Accessed: Nov 9, 2009.

Wagner, J.K., Dillon, J.A., Blythe, E.K., Ford, J.R., 2009. Dose characterization of the rad sourceTM 2400 X-ray irradiator for oyster pasteurization. Appl. Radiat. Isot. 67, 334-339.

These new, self-shielded X-ray irradiators will fulfil the requirements of processing capacity, dose rate, dose uniformity and ease of use required for research and many small-scale applications, including sterile insect technique, small animal research, radiation resistant microorganism research, medical device terminal sterilization and viral inactivation. They, therefore, provide a practical alternative to self-shielded gamma ray irradiators with associated safety.

References

Kirk, R.E., Gorzen, D.F. 2008. X-ray tube with cylindrical anode. USA Patent number 7,346,147 B2.

National Academy of Sciences, 2008. Radiation source use and replacement: Abbreviated version. The National Academies Press, Washington. Available from: http://www.nap.edu/catalog/11976.html Accessed: Feb 5, 2010.

Rad Source Technologies Inc., 2009. RS 2400 - X-ray high volume irradiator. Available from: http://www.radsource.com/products/products.php?id=rs2400 Accessed: Nov 9, 2009.

Wagner, J.K., Dillon, J.A., Blythe, E.K., Ford, J.R., 2009. Dose characterization of the rad sourceTM 2400 X-ray irradiator for oyster pasteurization. Appl. Radiat. Isot. 67, 334-339.